Back to top

We are specialized in manufacturing Lock Former Machines (Five Function), Beading Machines, Top Flange Machines, and many other products.

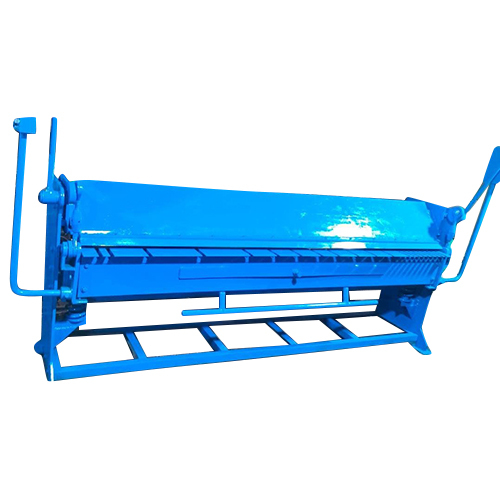

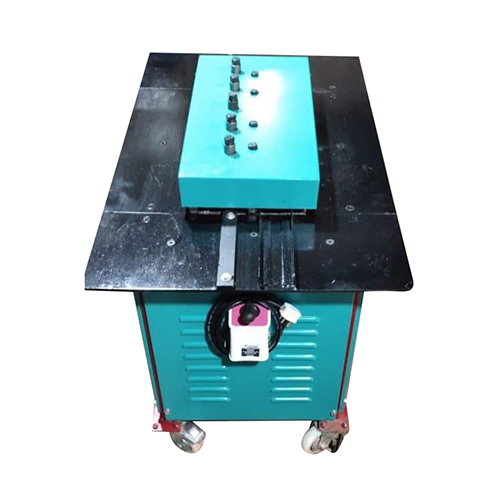

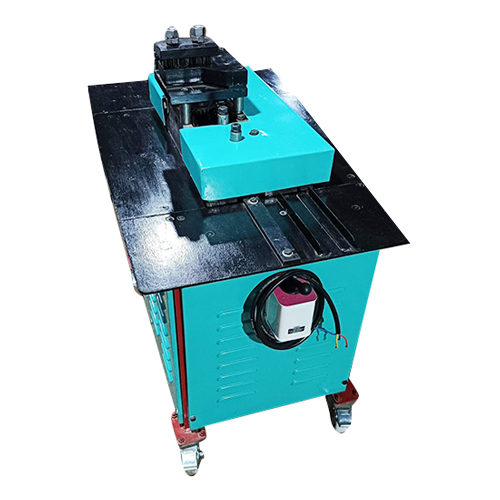

We, Al Hakimi Engineering Works, are based in Maharashtra, India as the reliable manufacturer, supplier, and exporter in the domain of industrial machines. We offer Beading Machines, Lock Former Machines (Five Function), Top Flange Machines, and Sheet Metal Folding Machines. We offer our range in standard and customized specifications so that they become suitable for different applications for application in diverse industries. All our machines are electrically operated and are constructed using aluminum alloys and other materials that are acquired from vendors after complete quality assurance. Further, all the machines are galvanized to prevent them from the hazards of corrosion and other factors. In our product range, we also have machines which are computer controlled.

We started business in 2009 and since then, we have accumulated the trust of numerous clients based all around the global market. They trust us not only for our quality products but also for our modern facilities and transparent business policies. We also possess a well-connected transport link across the country and abroad. Besides, we are advocates of quality packaging and use tamper-proof packing materials to ensure the safe transit of consignments.

Our Mentor

Mr. Mukhtar Ahmad Shaikh is a well known leader in the domain of industrial machines. He has gotten accolades from established institutions for his great work morals. With his direction, we have established a solid client support center, through which we offer responsive as well as personalized services to all clients.

Quality Assurance

Our integrity and quality commitment match international standards. We make sure that our clients are served with the best quality Sheet Metal Folding Machines, Beading Machines, Lock Former Machines (Five Function), and Top Flange Machines. Our expert quality control staff supervises the entire process of the quality examination conducted at our company. The process helps in ensuring complete quality assurance, which comes with the following benefits:

- Cost Savings: Good QA prevents quality issues, leading to cost savings by reducing scrap parts and returns.

- Efficiency Boosts: Fewer defective products allow for efficient resource allocation and pursuit of lucrative projects.

- Enhancements in Client Fulfillment: Compelling quality confirmation strategies result in way better items and their quicker conveyance.

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free